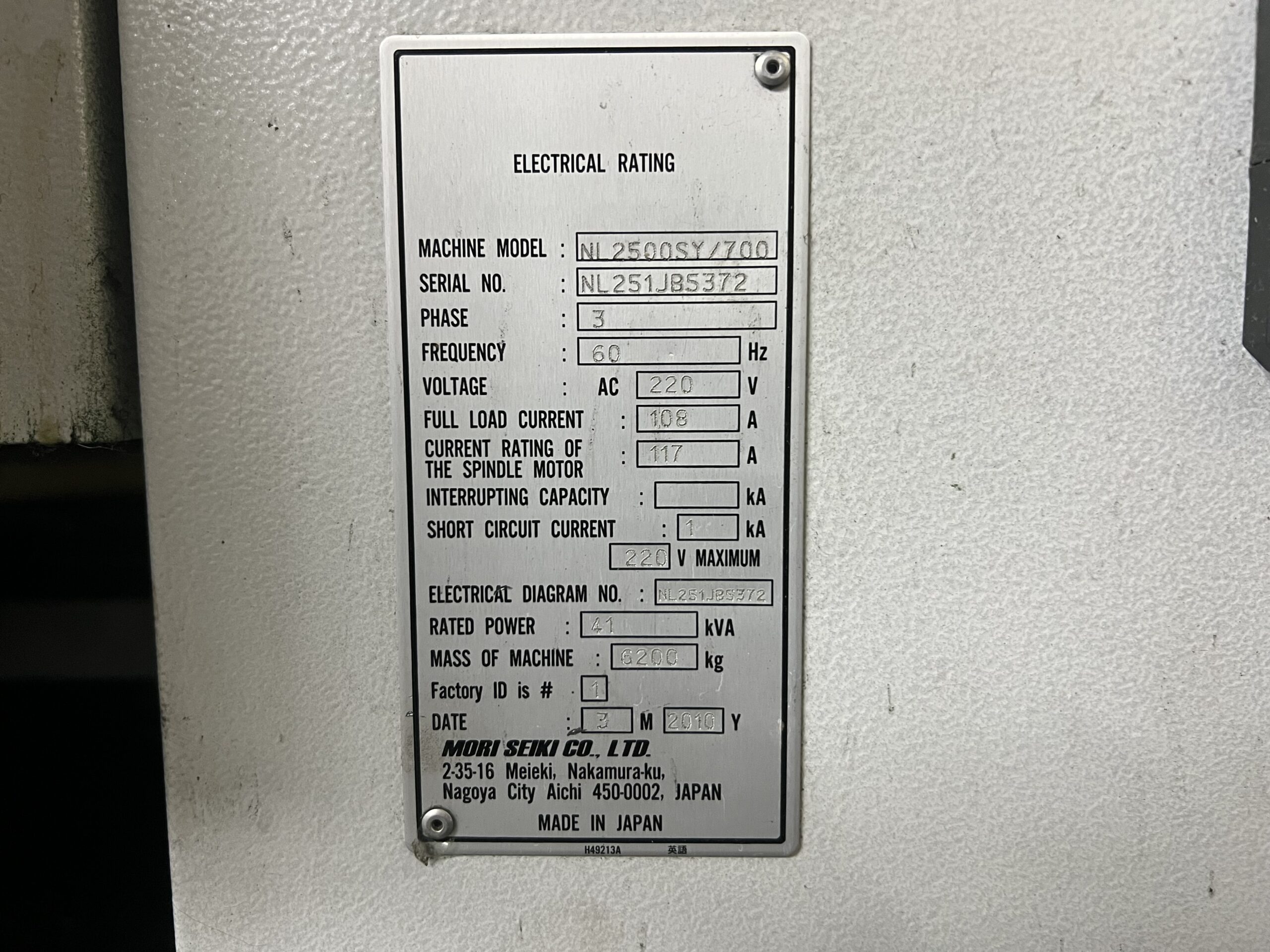

MORI SEIKI NL2500SY/700

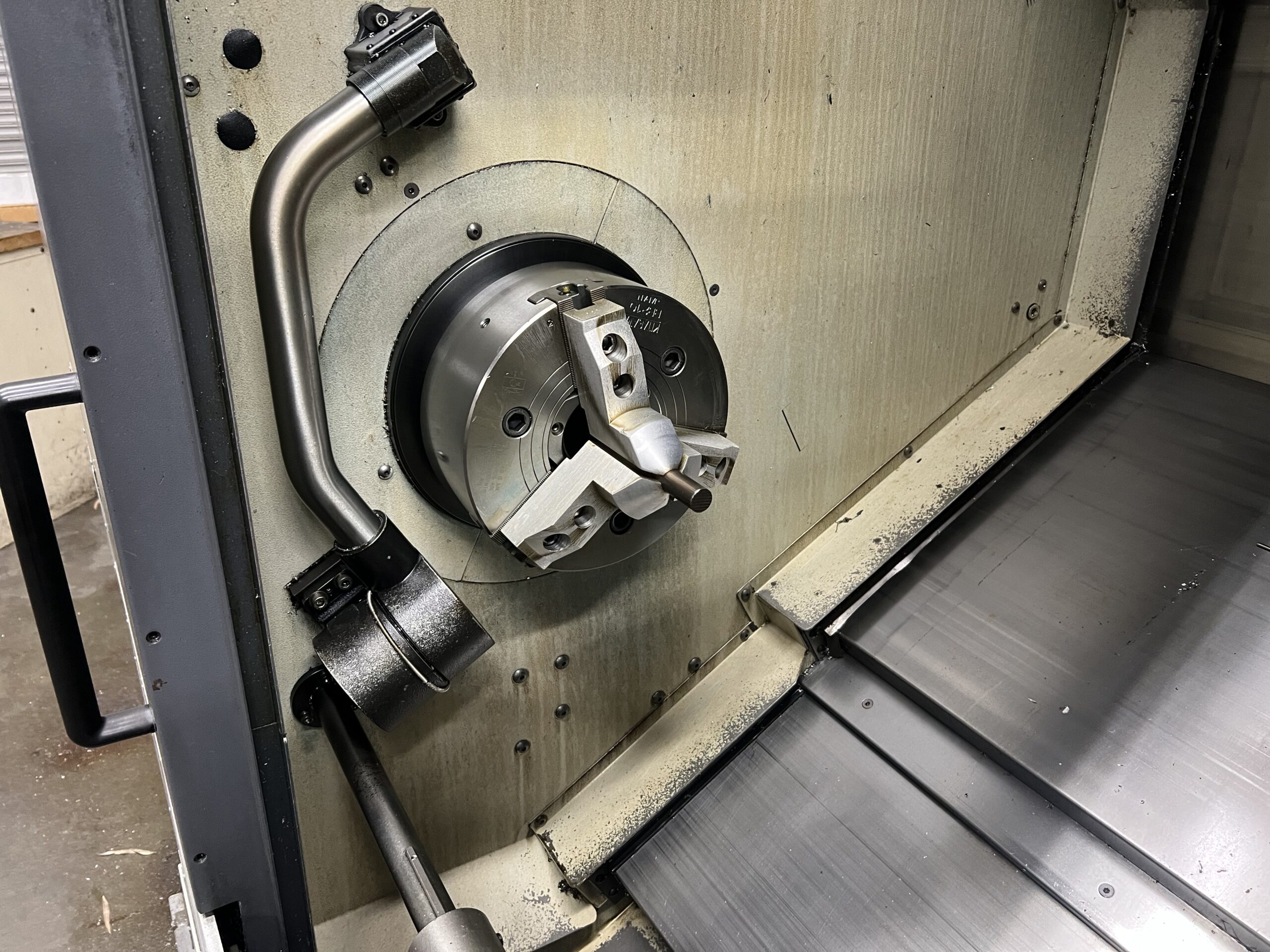

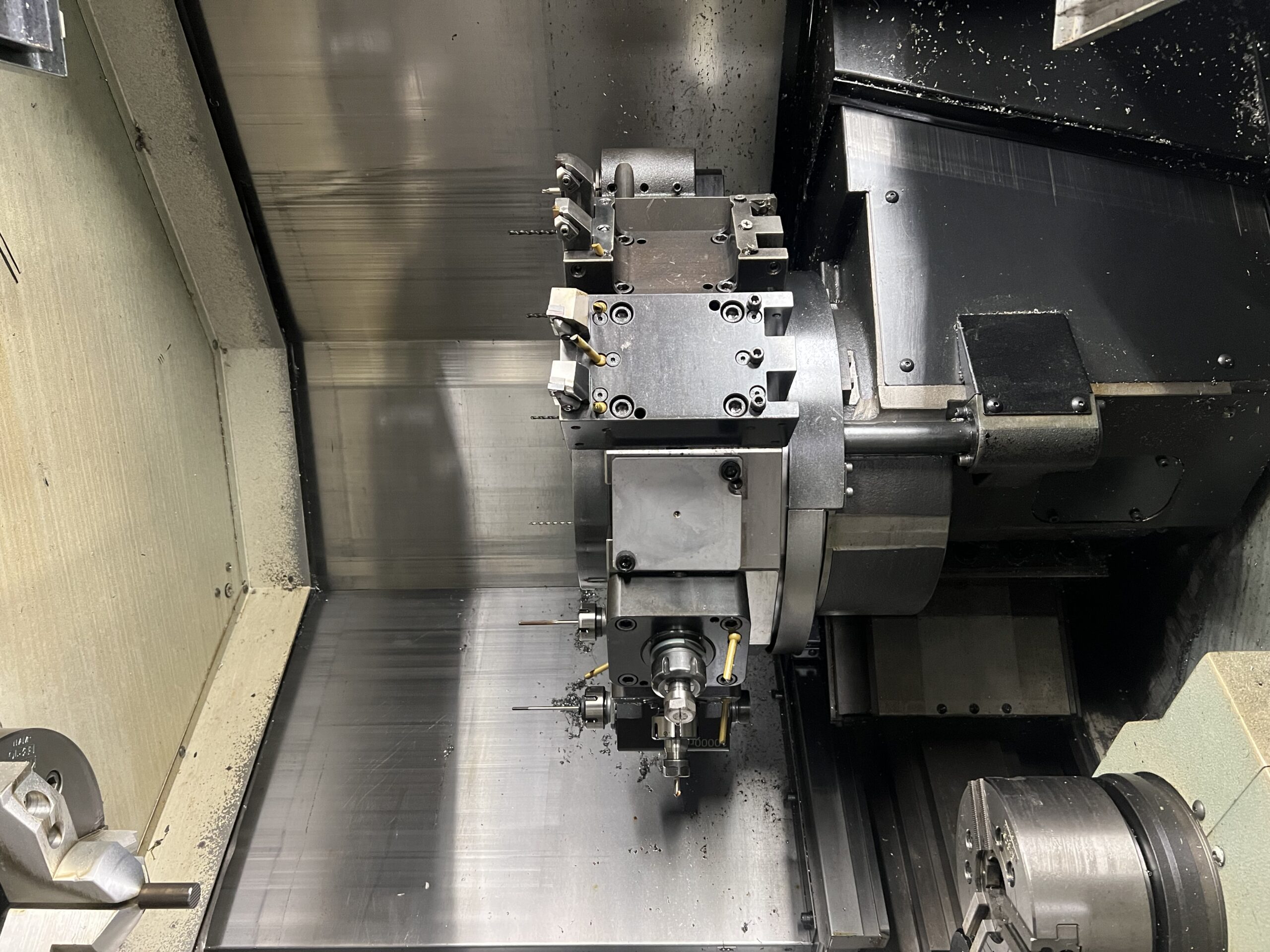

The MORI SEIKI NL2500SY/700 is a versatile mill-turn capable CNC turning center featuring a ~356–366 mm turning diameter, ~705 mm turning length, and Y-axis/sub-spindle/live tooling functionality with a 12-station turret. Equipped with a MORI SEIKI MSX-850 III CNC control and robust travel ranges (~260 mm X × ~±50 mm Y × ~795 mm Z), this machine is suited for comprehensive turning and mill-turn production work.

Availability: In Stock

Ask About This Description

MORI SEIKI NL2500SY/700 CNC Turning Center

Machine Type: CNC Turning Center / Mill-Turn (Y-Axis + Sub Spindle / Live Tooling capable)

Manufacturer: MORI SEIKI

Model: NL2500SY/700

Category: CNC Lathes / Mill-Turn Centers

Key Specifications

- Maximum Turning Diameter: ~356–366 mm (~14.0–14.4″)

- Maximum Turning Length: ~705 mm (~27.7″)

- Swing Over Bed: ~923–923.8 mm (~36.4″)

- Distance Between Centers: ~961 mm (~37.8″)

- X-Axis Travel: ~260 mm (~10.2″)

- Y-Axis Travel: ~±50 mm (~±2″)

- Z-Axis Travel: ~795 mm (~31.3″)

- Control Type: MORI SEIKI MSX-850 III or equivalent CNC

- Spindle Speed: Up to ~4,000 RPM

- Spindle Bore (Main): ~91 mm (~3.6″)

- Sub Spindle Bore: ~43 mm (~1.7″) (on sub-spindle units)

- Turret / Tool Stations: 12 stations (live tooling capable)

- Bar Capacity: ~80 mm (~3.15″)

- Rapid Traverse X/Z/B: Typical rapid rates up to ~30 m/min

- Weight: ~6,200 kg (~13,670 lbs)

- Typical Dimensions (L×W×H): ~3100×2050×2120 mm (~122″×80″×84″)

General Description

- The NL2500SY/700 is a versatile slant-bed CNC turning center with Y-axis capability and sub-spindle/live tooling options suitable for production turning and mill-turn applications.

- Commonly equipped with MORI SEIKI MSX-850 III CNC control and capable of handling a variety of turning tasks with live tooling, sub-spindle work, and C-axis indexing.

Notes to Buyers

- Specifications listed are typical values for the NL2500SY/700 series; actual configuration, options, and accessories should be verified with unit photos and inspection prior to bidding.

- Control make/model, tooling packages, and accessories (robot loaders, chip conveyors, etc.) may vary by individual machine.